CANtrace Help

A powerful CAN bus analyser software and diagnostic tool

A powerful CAN bus analyser software and diagnostic tool

CAN Settings is used for setting up your CAN interface correctly according to the CAN bus.

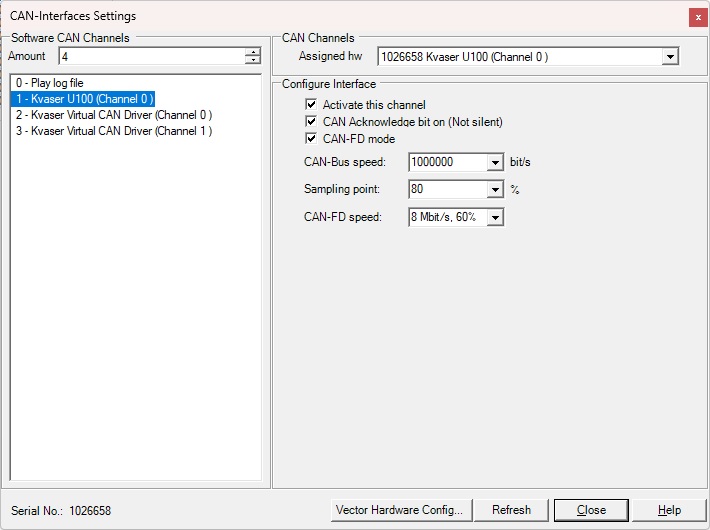

Figure 6.1 Kvaser Settings

Virtual channels can be used for development, test or demonstration purposes when you don’t have any hardware installed.

CAN Channels

The Assigned hw drop-down box lists the supported CAN interfaces that are plugged into the USB port of the computer. If you cannot find your hardware, try to click Refresh to rescan the hardware.

Software CAN Channel

You may configure which software channel you want to assign the CAN interface to. For example, in above figure, the Kvaser U100 is configured to software channel 2. It is good to know the software channel when you are for example sending a CAN message.

Activate this channel

If you have installed Kvaser drivers you may select Activate this channel in order to start using the Kvaser drivers.

CAN Acknowledge bit on (Not silent)

Here you can configure the CAN interface to work in silent mode (won’t transmit anything, won’t set the ACK bit of the received messages) if the CAN interface supports silent mode.

CAN-FD Mode

Here you configure the CAN interface to work in CAN-FD mode, If supported.

CAN-Bus Speed

Here you can select the baudrate of the CAN bus.

Sampling point

Here you can set the sampling point.

CAN-FD Speed

Here you can select the data bit rate and data sampling point.

6.1.1 Kvaser Classical CAN interfaces

Table 6.1 Supported baudrate and sampling point combinations are:

| Baudrate | Sampling point | Sampling point |

| 1 Mbit/s | 75% | 62.5% |

| 800 kbit/s | 80% | 60% |

| 500 kbit/s | 87.5% | 62.5% |

| 250 kbit/s | 87.5% | 62.5% |

| 125 kbit/s | 87.5% | 62.5% |

| 100 kbit/s | 87.5% | 62.5% |

| 83.3 kbit/s | 75% | |

| 50 kbit/s | 87.5% | 62.5% |

| 20 kbit/s | 87.5% | 62.5% |

| 10 kbit/s | 87.5% | 62.5% |

| 5 kbit/s | 68% |

6.1.2 Kvaser CAN FD interfaces

Table 6.2.1 Supported nominal bit rate and sampling point sets are:

| Nominal bit rate | Nominal sampling point |

| 1 Mbit/s | 80% |

| 800 kbit/s | 80% |

| 500 kbit/s | 80% |

| 250 kbit/s | 80% |

Table 6.2.2 Supported data bit rate and sampling point sets are:

| Data bit rate | Data sampling point |

| 1 Mbit/s | 80% |

| 2 Mbit/s | 75% |

| 4 Mbit/s | 70% |

| 5 Mbit/s | 62,5% |

| 8 Mbit/s | 60% |

Refresh

You can click Refresh to rescan the CAN interfaces that are connected to the PC.

Close

If you have finished configuration you can click Close to save and exit the CAN setting form.

Help

Help will open this CANtrace document in case you need some guidance while setting up CAN interfaces.

There are a few limitations to the Kvaser Interface when used in CANtrace.

TK Engineering Oy

Hovioikeudenpuistikko 13 as 3

65100 Vaasa, Finland

Kauppakatu 3 B

33200 Tampere, Finland

info@tke.fi

Phone: +358 6 357 6300