How can IT teams manage firmware updates on CAN devices?

Managing firmware updates on CAN (Controller Area Network) devices requires a structured approach from IT teams. The process involves maintaining device inventories, establishing secure update protocols, thorough testing in controlled environments, and implementing reliable rollback procedures. Effective firmware management for CAN networks balances operational continuity with necessary security and performance improvements. By leveraging specialized tools and following industry best practices, IT teams can ensure smooth, secure updates while minimizing downtime and maintaining system integrity across industrial environments.

Understanding the importance of firmware updates in CAN networks

Firmware updates are essential for maintaining the health, security, and functionality of CAN networks in industrial systems. These updates deliver critical security patches, performance improvements, bug fixes, and new features that keep industrial operations running efficiently.

In modern industrial environments, CAN networks connect various control systems, sensors, and actuators across machinery and equipment. As these systems face evolving operational demands and security threats, regular firmware updates become increasingly important. Outdated firmware can expose vulnerabilities that malicious actors might exploit, potentially leading to operational disruptions or data breaches.

Beyond security, firmware updates often improve communication protocols, enhance functionality, and optimize performance. For industries relying on J1939 protocol and other CAN-based communications, these updates ensure continued compatibility with new hardware and industry standards.

Proper firmware management is not just a technical requirement but a business necessity. It directly impacts system reliability, operational efficiency, and equipment longevity – all critical factors in maintaining competitive industrial operations.

What are the key challenges of managing firmware updates on CAN devices?

IT teams face several significant challenges when managing firmware updates across CAN device networks. The distributed nature of industrial CAN networks makes coordinating updates across multiple devices particularly complex, especially in geographically dispersed operations.

Hardware diversity presents another major hurdle. Industrial environments typically contain devices from various manufacturers, with different firmware architectures and update mechanisms. This heterogeneity complicates the creation of standardized update procedures and often requires specialized knowledge for each device type.

Operational continuity requirements further complicate the process. Many industrial systems must maintain high availability, making it difficult to schedule maintenance windows for updates. In critical infrastructure or manufacturing environments, even brief downtime can result in significant financial losses.

Validation challenges also exist. Ensuring that firmware updates function correctly across all interconnected systems requires comprehensive testing. Any compatibility issues between updated devices and existing systems can cause network-wide problems that may be difficult to isolate and resolve.

Additionally, limited bandwidth in CAN networks can make distributing large firmware packages challenging, requiring careful planning to avoid network congestion during update processes.

How can IT teams establish a reliable firmware update process?

Establishing a reliable firmware update process for CAN devices begins with comprehensive inventory management. IT teams should maintain detailed records of all CAN devices, including their current firmware versions, hardware specifications, and roles within the network. This foundation enables targeted update planning and helps identify potential compatibility issues before they occur.

Developing a staged approach is essential for minimizing risk. This typically includes:

- Creating a test environment that mirrors the production setup

- Testing updates thoroughly before deployment to production systems

- Implementing updates in phases, starting with non-critical systems

- Monitoring system performance at each stage

Robust rollback procedures must be established before any update begins. These should include creating system backups, preserving current firmware versions, and documenting clear steps to restore previous configurations if problems arise.

Scheduling updates during maintenance windows minimizes operational impact. For systems requiring continuous operation, redundancy arrangements should be implemented to maintain service while updates are applied.

Comprehensive documentation is equally important. Each update process should be documented with version changes, affected systems, test results, and any issues encountered. This creates an invaluable knowledge base for future updates and troubleshooting.

Finally, post-update verification processes should confirm that all systems function correctly and that no security vulnerabilities have been introduced. This might involve automated testing tools and manual inspection of critical functions.

What security considerations are essential when updating CAN device firmware?

Security during CAN device firmware updates requires addressing several critical areas to protect industrial systems from vulnerabilities. Authentication mechanisms should verify that firmware packages come from trusted sources before installation begins, preventing the introduction of malicious code into the network.

Encryption plays a vital role in protecting firmware packages during transit across the network. Without proper encryption, firmware updates could be intercepted and modified by attackers in man-in-the-middle scenarios. This is particularly important for updates delivered remotely or across exposed network segments.

Access control policies must restrict firmware update capabilities to authorized personnel only. These policies should follow the principle of least privilege, ensuring that technicians can only update specific devices relevant to their responsibilities.

Integrity verification is essential before and after updates. Checksums and digital signatures help confirm that firmware packages remain unaltered throughout the update process, while post-update verification ensures all security features are functioning correctly.

Security logging and monitoring should be implemented to track all firmware update activities. These logs create an audit trail that can help identify unauthorized access attempts and provide valuable information during security investigations.

Regular security assessments of firmware update processes identify potential vulnerabilities before they can be exploited. These assessments should review both technical controls and procedural aspects of the update process.

How can automated tools improve CAN firmware management?

Automated tools significantly enhance efficiency and reliability in CAN firmware management by streamlining complex processes. Centralized management platforms allow IT teams to orchestrate updates across multiple devices from a single interface, dramatically reducing the time and effort required for firmware deployment.

Diagnostic utilities help identify devices requiring updates by scanning networks to inventory connected devices and their current firmware versions. These tools often provide detailed reports highlighting outdated firmware, potential compatibility issues, and security vulnerabilities that need addressing.

Version control systems maintain firmware libraries with comprehensive tracking of changes between versions. This ensures teams always know exactly what changes are being implemented and provides the foundation for rollback capabilities if needed.

Automated testing frameworks verify system functionality before and after updates, running predefined test scenarios to confirm that critical operations continue functioning correctly. These tools can detect subtle issues that might otherwise go unnoticed until they cause operational problems.

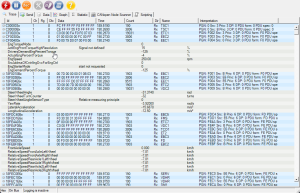

Specialized solutions like CANtrace offer comprehensive diagnostics and monitoring capabilities for CAN networks, providing visibility into network communication and helping identify potential issues during and after firmware updates.

Deployment scheduling tools help IT teams coordinate updates during optimal time windows, reducing impact on operations while ensuring updates are completed within required maintenance periods.

Together, these automated solutions transform firmware management from a potentially risky manual process into a streamlined, reliable operation with improved security and reduced downtime.

Key takeaways for effective CAN firmware management

Effective management of firmware updates on CAN devices requires a strategic approach that balances technical requirements with operational needs. Proactive planning is fundamental – establishing update schedules based on criticality, security implications, and operational windows minimizes disruption while maintaining system integrity.

Creating detailed documentation of all update procedures, including device inventories, firmware versions, and configuration details, builds institutional knowledge that proves invaluable during troubleshooting and future updates.

Implementing a testing methodology that includes lab validation before production deployment significantly reduces the risk of unexpected issues. This should involve testing not just the updated device but its interactions with the entire network.

Securing the entire update process from package verification to deployment protects against increasingly sophisticated cyber threats targeting industrial systems. This multi-layered security approach should address all potential vulnerabilities in the update chain.

Leveraging specialized tools designed for CAN network management streamlines processes and provides deeper visibility into system behavior during updates. These tools can automate many aspects of the update process while providing essential monitoring capabilities.

As industrial systems become more complex, collaboration between IT and OT (Operational Technology) teams becomes increasingly important. Establishing clear communication channels and shared responsibility models ensures all perspectives are considered during firmware update planning.

For organizations looking to improve their approach to CAN network management, examining successful implementations can provide valuable insights. Our Case study collection offers examples of effective firmware management strategies across various industrial applications.

By adopting these practices, IT teams can transform firmware updates from potential operational risks into opportunities for system improvement and enhanced security, ensuring industrial CAN networks remain reliable, secure, and optimized for performance.