TKE CiA 408 Four-Edge Valve Controller

TK Engineering Oy has developed a CiA 408 device profile compliant four-edge valve controller. The four-edge valve controller simplifies the control of hydraulic cylinder piston velocities. The piston velocity is controlled through a standardized CAN communication interface specified by the CiA 408 device profile. The modular implementation of the controller enables it to be easily integrated into control systems.

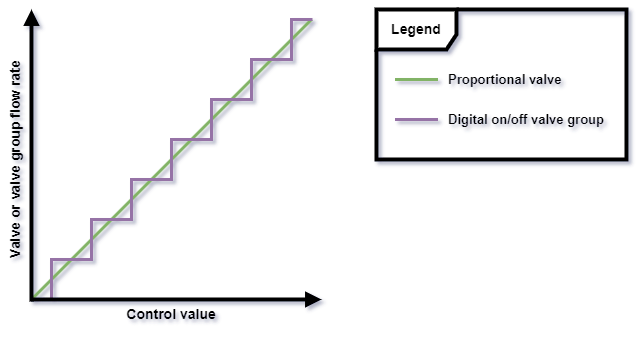

control edge is controlled with its own valve or valve group. Proportional valves can be replace with groups of parallel digital on/off valves. With different control combinations of the valve group, e.g. different valves are open and closed, varying flow rates are achieved. This enables functionality of a proportional valve to be replicated using digital valves. [1] This notion is displayed in the figure 1.

Figure 1: Proportional valve functionality with digital on/off valve group.

Digital valves are more cost-efficient compared to proportional valves. By replacing proportional valves with digital valve groups, higher flow rates and work pressure can be achieved with less implementation cost.

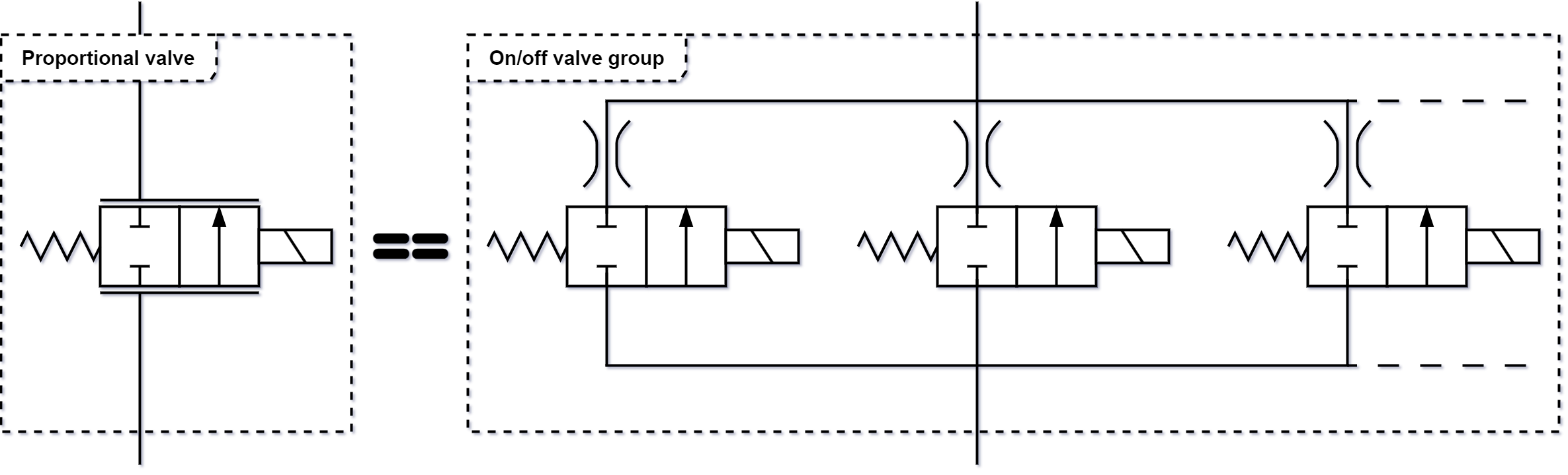

As digital on/off valve groups act as a proportional valves they can be displayed using a simplified symbol. This notion is displayed in figure 2.

Figure 2: Proportional valve and an on/off valve group [2].

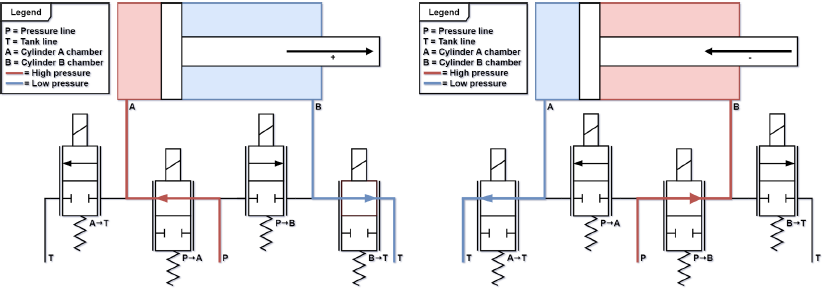

Four-edge control consists of four control edges each consisting of a valve or a valve group. By controlling the flow rate of the control edges the hydraulic cylinder piston velocity is controlled. The figure 3 displays hydraulic cylinder velocity control to positive and negative working direction.

Figure 3: Four-edge control of hydraulic cylinder piston velocity.

By connecting the pressure line to the working port A and tank line to the working port B the piston velocity is controlled to the positive working direction (figure 3, left). Connecting the pressure line to the working port B and tank line to the working port A the piston velocity is controlled to the negative working direction (figure 3, right). By varying the working port flow rates the piston velocity is altered. By adding a position sensor for the hydraulic cylinder, position based control can be implemented.

The Role of CANopen Device Profiles and Four-Edge Valve Controllers

CANopen specifications include profiles that specify process data, configuration parameters, and diagnostic information for CANopen devices. Device profiles describe interfaces for logical devices as defined in CiA 301. [4] CiA 408 device profile specifies the logical interface for hydraulic devices. The profile specifies mandatory and optional configuration parameters and diagnostic information [5]. The TKE CiA 408 four-edge valve controller implements the logical interface specified in the CiA 408 device profile. In addition some manufacture specific configuration parameters have been implemented to increase the configuration management efficiency of the device.

With the use of a four-edge valve controller the control of hydraulic cylinder piston velocities is simplified. The complex control logic of a four-edge control is hidden beneath a simple standardized interface. This enables the control control system designers to easily implement control for hydraulic cylinders. The TKE four-edge valve controller contains a standardized control interface specified by the CiA 408 device profile. The standardized interface of the controller enables it to be easily integrated into different control systems. With configuration management through the devices CANopen object dictionary the controller can be easily adapted to different use cases.

Implementing TKE CiA 408 Four-Edge Valve Controllers in Translifter Control Systems

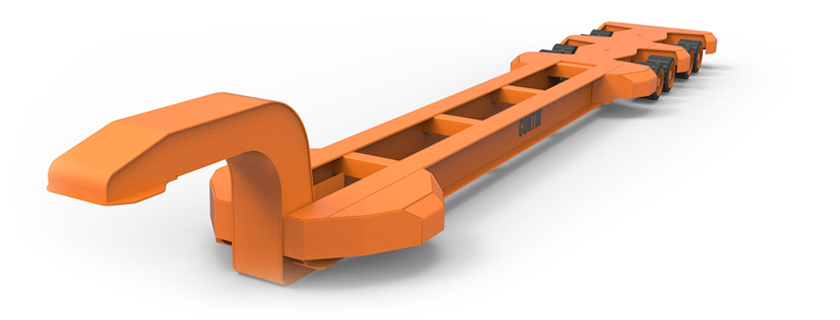

The TKE CiA 408 four-edge valve controller is used in a translifter control system implementation. The four-edge controllers found in the system are used for controlling the hydraulic cylinders that alter the translifter lifting height and turning angle. Illustration of the translifter containing the four-edge controllers is displayed in figure 4.

With the use of TKE CiA 408 four-edge valve controllers a distributed modular control system was created. With distributed modular control system design the cost-efficiency, scalability and re-usability of the system was increased.

Figure 4: Illustration of translifter containing TKE CiA 408 four-edge valve controllers [3].

References

[1]J. Tervonen, “Pyöräkuormaajan energiankulutuksen tutkiminen.” Accessed: Mar. 17, 2024. [Online]. Available: https://trepo.tuni.fi/bitstream/handle/123456789/22284/tervonen.pdf?sequence=3&isAllowed=y

[2]H. Saha, “CANopen controller for independent metering control valves”, Accessed: Mar. 17, 2024. [Online]. Available: https://tke.fi/wp-content/uploads/2023/09/

cnlm_233_p14_canopen_controller_for_independent_metering_control_valves_dr_heikki_saha_tke.pdf

[3]“Translifters – Contik Group Oy.” https://contik.fi/en/translifters/ (accessed Mar. 17, 2024).

[4]“CAN in Automation (CiA): CANopen profiles,” Can-cia.org, 2013. https://www.can-cia.org/can-knowledge/canopen/canopen-profiles/ (accessed Jan. 08, 2020).

[5]“CAN in Automation (CiA): CiA 408: CANopen profile for hydraulic devices,” www.can-cia.org. https://www.can-cia.org/can-knowledge/canopen/cia408/ (accessed Mar. 17, 2024).